Waste to Energy

Challenges

Every year we dump a

massive 2.12 billion tons of waste

on the planet.

In a world with changing demographics and increasing expenditure on consumables, the amount of solid waste generated is alarming. Every year we dump a massive 2.12 billion tons of waste on the planet. If all this waste was put on trucks, they would go around the world 24 times.

There is a pressing need to use our resources in the best possible way. This involves reducing the generation of waste, ensuring high-quality recycling, and using residual waste for efficient and clean energy generation.

WHAT IS

Waste to energy (WtE) is an emerging and innovative set of technologies that plays a vital role in the waste management system. It involves the process of recovering energy in the form of heat or electricity from residual waste that cannot be recycled. This type of energy is a renewable energy source as non-recyclable waste can be used over and over again to create it. Over time, this reduces global warming and makes our environment better.

Waste-to-energy plants burn municipal solid waste (MSW), often called garbage or trash, to produce steam in a boiler that is used to generate electricity.

MSW is a mixture of energy-rich materials such as paper, plastics, yard waste, and products made from wood. For every 100 pounds of MSW, about 85 pounds can be burned as fuel to generate electricity. Waste-to-energy plants reduce 2,000 pounds of garbage to ash weighing about 300 pounds to 600 pounds, and they reduce the volume of waste by about 87%.

What are MSW Components

Municipal solid waste (MSW), often called garbage, is used to produce energy at waste-to-energy plants and at landfills. MSW contains.

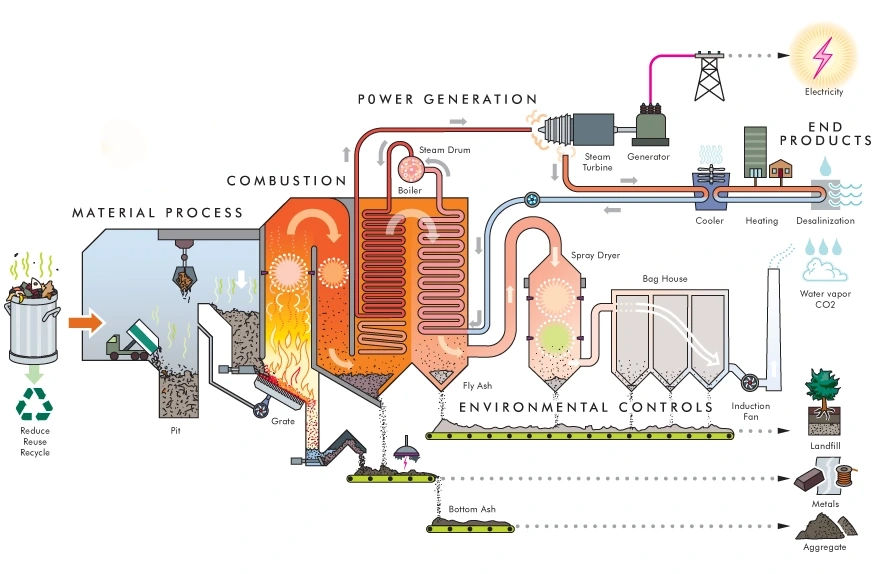

The Technologies

There are different types of waste-to-energy systems or technologies. The most common type is the mass-burn system, where unprocessed MSW is burned in a large incinerator with a boiler and a generator for producing electricity (see illustration below). Another less common type of system processes MSW to remove most of un combustible materials to produce refuse-derived fuel (RDF).

The Process

The process of generating electricity in a mass-burn waste-to-energy plant has seven stages:

- Waste is dumped from garbage trucks into a large pit.

- A giant claw on a crane grabs waste and dumps it in a combustion chamber.

- The waste (fuel) is burned, releasing heat.

- The heat turns water into steam in a boiler.

- The high-pressure steam turns the blades of a turbine generator to produce electricity.

- An air pollution control system removes pollutants from the combustion gas before it is released through a smokestack.

- Ash is collected from the boiler and the air pollution control system.

The Output / Benefits

Waste-to-energy plants make steam and electricity

MSW is usually burned at special waste-to-energy plants that use the heat from the fire to make steam for generating electricity or to heat buildings. In 2020, WTE plants generated about 13.5 billion kilowatt-hours of electricity from burning about 25 million tons of combustible MSW for electricity generation.

Biomass materials accounted for about 61% of the weight of the combustible MSW and for about 45% of the electricity generated. The remainder of the combustible MSW was non-biomass combustible material, mainly plastics.

Waste to energy is the upcoming waste management method aimed at: -

Thus, WtE will be a valuable local source of secure, stable, and climate-friendly energy.

Statistics

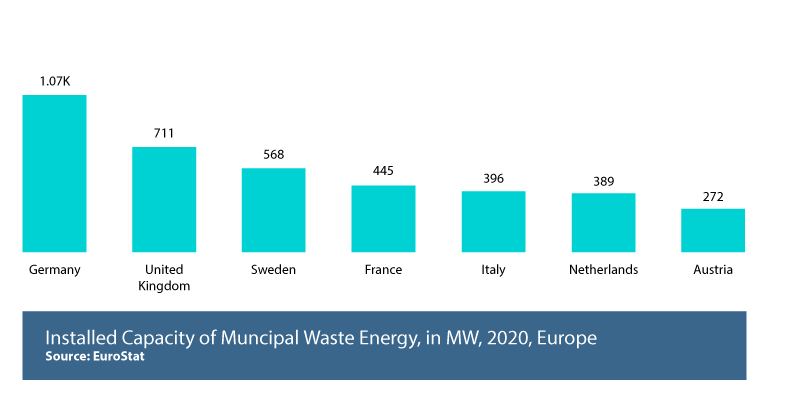

Many countries use waste-to-energy plants to capture the energy in MSW. The use of waste-to-energy plants in some European countries and in Japan is relatively high, in part because those countries have little open space for landfills.

The European waste-to-energy (WtE) market reached USD 17.28 billion, and it is anticipated to reach USD 24.12 billion by 2027, registering a CAGR of 4.2% during the forecast period. Thermal technology is expected to dominate the waste-to-energy market in the coming years, owing to the increasing development in incineration and gasification technologies and the growing amount of waste generated in European countries.

Germany has witnessed significant development in the waste-to-energy industry in the past few years. The country has dominated the market across the European region, with increasing efforts taken by the government in adopting better MSW management practices. The installed capacity of waste energy in Germany reached 1,072 MW in 2020, followed by the United Kingdom and Sweden, with 711 MW and 568 MW, respectively.

A new project, the Wiesbaden WtE plant is scheduled to open by 2024 in the central-western city of Germany. It will have the capacity to process 600 ton of municipal solid waste per day to produce 22MW worth of electricity and provide 40MW-scale district heating.

An established and successful project in UK is the Lincolnshire’s Energy-from-Waste facility. It was started in 2013 and provides a sustainable way to dispose of residual waste that otherwise would end up in landfill. It can treat 150,000 tonnes of residual household and commercial waste p.a. and produce 11 MW electricity (approx) and has the potential to supply heat to the local community. Ramboll Uk Ltd. in collaboration with the County Council as its lead technical advisor has provided fast-track services and results.

With these technologies developing by day and their acceptance increasing amongst households and industrial set-ups worldwide, waste to energy is seen as a development tool worldwide.

Case Studies

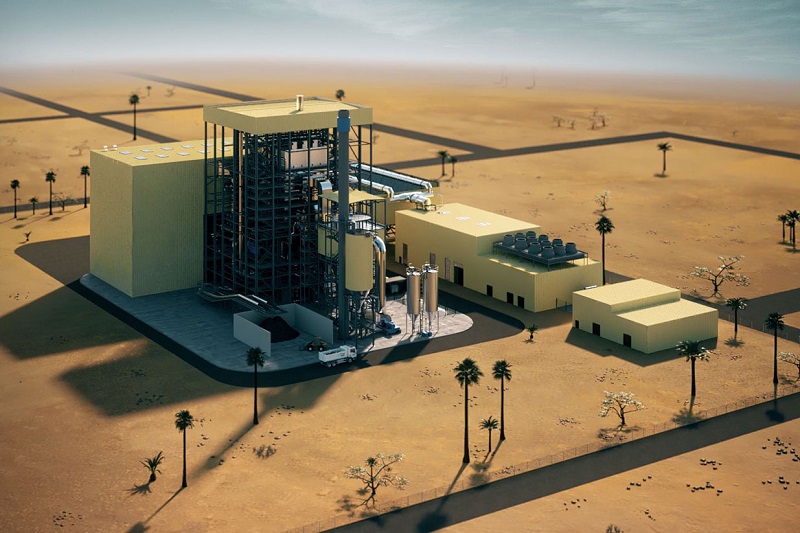

Masdar, in partnership with Bee’ah, the Middle East’s leading and award-winning environmental management company, is developing a cutting-edge waste-to-energy plant in the Emirate of Sharjah. It is the first commercial waste to energy facility in the Middle East.

Bee’ah collects approximately 2.3 million tonnes of waste from nearly one million households in Sharjah each year, diverting around 70 percent of its collected waste from landfill to its recycling waste management facilities. This facility will process more than 37.5 tonnes per hour of municipal solid waste to generate electric power. The waste-to-energy incinerating process will convert the waste into produced heat which is then used to drive a steam turbine. The net electrical power produced will be up to 30 MW which will be supplied directly to the Sharjah electricity grid. This project displaces almost 450,000 tonnes of CO2 emissions per year and saves 45 million m3 natural gas per year.